ARTISAN MOSAICS IN SPILIMBERGO

VARNISHES

Varnishes are erected from plates called "pizzas", which are 10 mm thick with a diameter of about 25/30 cm. The weight of a plate varies from about 1,800 kg to 2,200 kg.

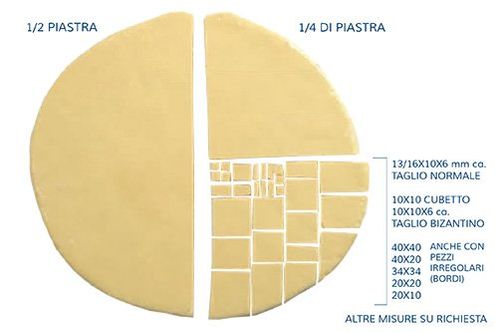

Varnishes are sold in whole plates, half plates (about 1 kg) and 1/4 plates (about 1/2 kg).

About 25 kilograms of varnished plates are required to cover an area of one square metre.

We have about 2,500 to 3,000 colours in various shades in stock that you can choose from directly in our factory by appointment.

Normal varnishes:

Click on the image to view the colour code

Thin varnishes:

Click on the image to view the colour code

Special varnishes:

Click on the image to view the colour code

Imperial varnishes:

Click on the image to view the colour code

Complexion varnishes:

Click on the image to view the colour code

Golds:

Click on the image to view the colour code

Warning: because our tiles are cut by hand, with the aid of a manual shear, they are not perfectly regular, but this is an asset that identifies our artisan craft.

Cutting tiles

Approximately 14 kilograms of normal-cut varnishes are needed to cover an area of one square metre.

The standard cuts are:

- 34x34 mm cut with irregularities (edges of the plate)

- normal cut (as per sample) approximately 13-16x10x6 mm

Cuts on request (ask for prices)

- 10x10x10mm cube

- Byzantine cut approximately 10x10x6 mm

- 40x40x10 mm chosen or irregular

- 40x20x10 mm chosen or irregular

- 20x20x10 mm chosen or irregular

- 20x10x10 mm

(irregularities refer to the edges of the tile)

Warning:

because our tiles are cut by hand, with the aid of a manual shear, they are not perfectly regular, but this is an asset that identifies our artisan craft.

TILES from SPILIMBERGO TO make YOUR PROJECTS come to life

We at Mario Donà Mosaici will help you make your ideas come to life. Every day, at our headquarters in Spilimbergo, we produce glass tiles that are perfect for any kind of production. We offer a wide range of colours and thicknesses. We also create special cuts based on the needs of our customers upon request.

Our varnishes: the result of a curated selection

Our products are subjected to chemical analysis to ensure that they are always stable over time.

Varnished shades are made using a meticulous procedure that utilizes the best products available for processing, so as to provide customers with a product of excellent quality.

Our experience is handed down from generation to generation. We scrupulously keep our family secret to produce quality glass, follow a meticulous artisan procedure and forge varnishes in front of the fire's flames, just like we did back then.